The ESP Power Cable developed by Alenntronics is engineered to meet the high-quality standards of the oil and gas industry, ensuring outstanding electrical performance even under extreme high-temperature and corrosive wellbore conditions.

To ensure maximum reliability and safety, each cable is built using advanced materials and precision manufacturing processes:

Oxygen-free copper conductors can be tinned or wrapped with polyimide film to enhance insulation strength and temperature resistance.

The insulation layer is made of premium EPDM or polypropylene, offering superior electrical stability in harsh environments.

A lead sheath layer provides effective protection against gas and corrosive liquid intrusion. For wells with milder conditions, butyl rubber sheaths are available as a cost-effective alternative.

The cushioning layers combine oil-resistant polytetrafluoroethylene (PTFE) and nylon belt winding, providing excellent mechanical protection and flexibility.

The armor layer can be customized using carbon steel galvanized, 304, 316, 316L, or Monel, depending on specific well conditions.

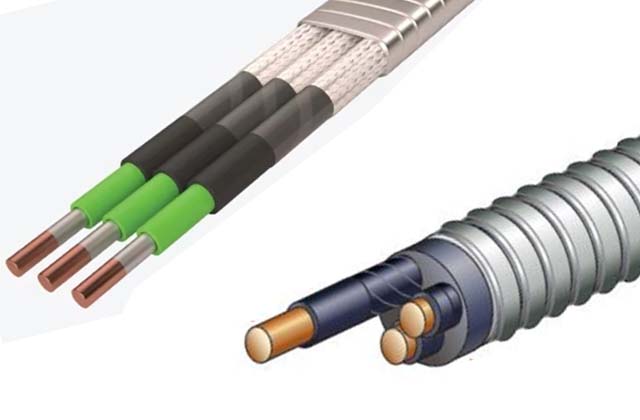

Cable configurations are available in both flat and round profiles, offering adaptability for various ESP installations.

With its high insulation performance, corrosion resistance, and temperature endurance, the Alenntronics ESP Power Cable ensures long-term operational stability and reliability for modern Electric Submersible Pump (ESP) systems.