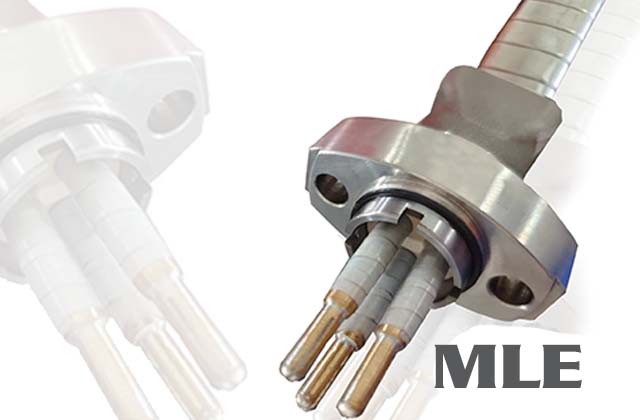

In an Electric Submersible Pump (ESP) system, the connection and sealing between the motor and the cable are critical for ensuring stable performance and long-term reliability. Extreme wellbore temperatures, motor-generated heat, and gas penetration pose serious challenges to the Motor Lead Extension (MLE).

To meet these demanding conditions, Alenntronics has re-engineered the traditional MLE design and joint structure. By using special high-performance cable materials and a reinforced joint configuration, we have significantly reduced rubber components and incorporated advanced high-temperature and corrosion-resistant materials.

This innovation enhances the MLE’s durability and ensures optimal performance in high-temperature and corrosive wellbore environments.

Field applications have proven that Alenntronics MLE demonstrates superior reliability and extended service life compared to conventional products, offering unmatched adaptability to heat, pressure, and corrosive gases.

Key Benefits of Alenntronics MLE:

Excellent sealing performance under high temperature and pressure

Enhanced corrosion resistance in gas-rich environments

Long-lasting insulation integrity

Reliable connection between ESP motor and power cable

Proven durability through extensive field testing

Choose Alenntronics Motor Lead Extension (MLE) — engineered for extreme environments and trusted for reliability in modern oil and gas operations.